Search Posts

| sun | mon | tue | wed | thu | fri | sat |

| 1 | 2 | 3 | 4 | 5 | ||

| 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| 13 | 14 | 15 | 16 | 17 | 18 | 19 |

| 20 | 21 | 22 | 23 | 24 | 25 | 26 |

| 27 | 28 | 29 | 30 | 31 |

Subscribe

Recent Posts

The Historic Dimension Series

A student publication series by the UNCG Department of Interior Architecture

The Art of Brick: Brickmaking in Piedmont North Carolina

Martha L. Canipe Fall 2017

"No man ever wetted clay and then left it, as if there would be bricks by chance and fortune."

- Plutarch

The use of brick as a building material can be documented archaeologically to the very earliest human attempts at construction, favored in large part because it requires only three natural ingredients: clay, sand, and water. These components can be found throughout the world, allowing bricks to be made on demand and on site. Producing a properly made, durable brick, however, requires an understanding and mastery of each step in the brick making process, whether it be handmade or machine-made.

Creating a Brick

There are a distinct set of steps in making a brick, and although the system has beenmechanized today to produce lighter, more uni.form bricks, the sequence has remained basically the same. The process beginsby digging the clay (often referred to as "winning" the clay). Prior to mechanization, brickrnaking was customarily a seasonal endeavor, only attempted during the summer months and worked in around planting and harvest periods by whomever had the time or a bit of experience. Clay needed to be weatherized, so it was dug in the fall, and left outside during the winter, allowing the colder weather and frost to temper the clay. The following spring, it was spread into a thin layer that was thenfurther softened (pugged) by having oxen or horses systematically walk or pull a heavy wheel over the clay, thus pulverizing any larger stones.

Once softened, the clay was ready for tempering, which is simply mixing sand and/or water to the clay to create the needed consistency . This step often required experimentation to arrive at the specific combination of ingredients suited to the local clay, was site specific, and likely needed to be recreated at each building site. As mechanization progressed, these two steps were combined through the usage ofa pug-mill - a machine originally used to temper clay for pottery, but soon adapted for the brickmaking process.

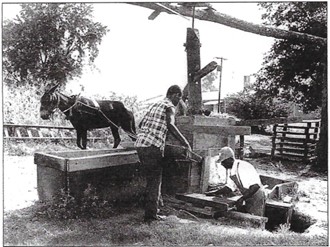

Pug-mills incorporated a vertical cylinder enclosing a setup of both horizontal and vertical steel knives into which the clay/ sand/water mixture was poured. The knives mixed and softened the clay as it passed through, again pulverizing any larger objects. The first pug-mills were small enough to be moved from site to site, and though originally powered by horses or mules, were eventually converted to steam power. Both methods were used well into the twentieth century depending on location and economic circumstances (McKee, 43; Peterson, 84).

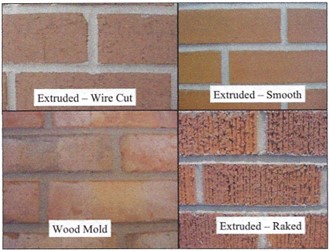

Once the clay is tempered, it is ready for molding. For thousands of years, this consisted of the soft mud being hand pushed into a wooden mold that had already been sprinkled with sand (occasionally water) to prevent sticking. A wooden scrap was then drawn across the top to remove excess clay. A single mold was filled and emptied repeatedly until the advances of mechanization, when numerous molds could be filled simultaneously. These advances also allowed use of a drier clay mixture (often shale), leading to both the pressed (dry-pressed) and extruded methods of bri production. The dry press method pushed clay into molds that were then hard pressed by a plunger, forcing the clay into a more uniform shape than was possible by hand. A different mechanized process, known as the extruded method, forced what was called stiff clay out of a machine in a continuous bar that was then cut into uniform sized bricks by either piano wire or a steel knife. Both the pressed and extruded methods of brick production came into use in the early to mid nineteenth century, but all three methods overlapped well into the twentieth century. Hand carved presses, later machine presses, could be created with initials, names, numbers or brands-often denoting individual brickmakers or companies.

Fig. 3: A clamp built by George Black in the late 1900s much like one from the 1700s.

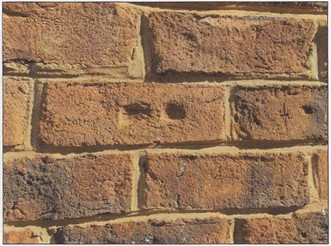

Molded brick (also referred to as green brick) needs to be dried prior to the firing process. In the original soft mud, hand molded process, this meant removing the brick from the mold, and allowing it to dry a few hours before attempting to stack the still moist bricks into what are called hacks. Early hacks were usually covered by some type of roof as basic protection from the weather, but still experienced a high loss ratio. (Bricks made by this method are often marked by fingerprints, animal prints, hay marks and markings created during the stacking process, helping identify them as hand-made brick.) Attempts were made to speed up the drying process through strategically placed fires in drying sheds, but real progress occurred with the arrival of steam power. Stearn from boilers could be pumped continuously into drying sheds, substantially shortening the drying process, although this method was just as quickly replaced by "drying tunnels." Bricks were now loaded onto kiln cars, and pulled through the tunnel at a consistent speed, rate of humidity, and temperature, thus better regulating water content in the clay.

The final steps of brickrnaking are the firing (burning) of the brick, which includes a gradual cooling period to avoid cracking; and load sorting, the process of manually separating bricks by quality and color. Until modernization, the firing process was possibly the most demanding, and potentially most destructive, portion of the brickrnaking process. Bricks are typically fired in kilns, and until (and into) the Industrial Age, they were hand-built on site. Generally referred to as clamps, they were built with green bricks as seen above in figure 3. Bricks were stacked throughout the clamp with just enough space for hot air to circulate. Fires were built in the tunnels below, fueled either by wood or coal that required constant replenishment and monitoring through firings that could last two weeks.

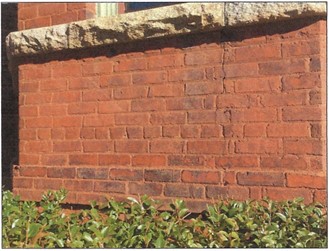

Maintaining a consistent bum temperature required experience, and could vary with clay consistency at each individual site. It was a given that bricks towards the outside would often under fire while bricks closest to the highest heat frequently burned on the ends, so bricklayers learned how to utilize these bricks of different strengths for diverse purposes in construction as the time, energy and resources required for the brickrnaking process simply could not be wasted.

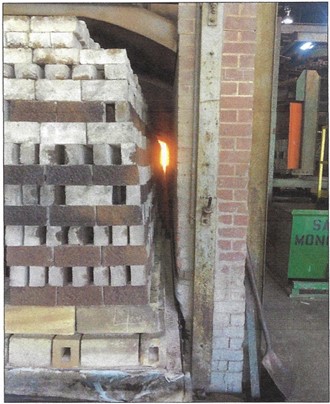

As brickrnaking mechanized, experimentation with steam and gas power eventually produced the tunnel kiln (developed along with the tunnel dryer in the mid nineteenth century). This system allowed a kiln car of bricks to gradually warm to the needed temperature, maintain that temperature over several days, then slowly cool as the car exited the tunnel- andisstill the standard process used today (Elliott, 44).

Fig. 4: George Black with his mule-powered pug-mill.

Fig. 4: George Black with his mule-powered pug-mill.

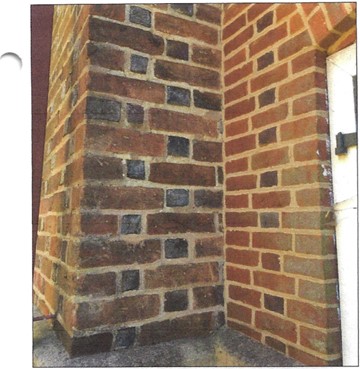

Creating Color in Brick

The final color of a brick depends on three things: the natural chemical composition of the clay or shale, the firing temperature, and the method of firing. Every clay deposit is created by specific geological circumstances, therefore, even deposits in close proximity to each other may produce notably different colors of brick. Brick buildings constructed in the Piedmont area of North Carolina prior to standardized production will normally have a large color differentiation. The Piedmont Plateau of the eastern United States contains a large amount of clay soils (Ultisols) with a particularly high iron oxide content, resulting in red brick when fired between 900 and 1000 degrees Celsius. Raising that temperature produces a plum or purple brick, higher again, a brown or grey. The lower the iron content, the whiter the brick, however, additives can be mixed with the clay to alter the final color. For example, adding calcium carbonate or magnesium oxide will produce beautiful yellow brick, even though this color occurs naturally in clay deposits as well. Finally, color (and glazing) can also be created by reducing the oxygen supply in the kiln towardsthe end of the firing (Broeksmit and Sullivan, 46; Henry, 406).

Learning how to produce a specific color of brick based on the chemical makeup of clay/shale deposits is an art. Mastering that art demands expertise in clay content, natural chemical additives, and the firing process-and even today involves a certain amount of trial and error.

Fig. 5: A hack of bricks entering the tunnel kiln at Old Carolina Brick Company.

Fig. 5: A hack of bricks entering the tunnel kiln at Old Carolina Brick Company.

Brickmaking in the Piedmont, North Carolina Brick manufacturing in North Carolina can be documented from the 1600s, in large part because of the abundance of, and easy access to, both clay and sand. The earliest examples are found in the eastern region of the state, by brickmakers who had typically relocated from eastern Virginia. Clay in the coastal region, however, was of a poorer quality than the Piedmont, thus, most brick used in coastal areas was imported from northern cities like Philadelphia rather than produced locally. As a result, craftsmen generally included brickmaking and bricklaying as two of their skills, rather than specializing in them. Catherine W. Bishir, in Architects and Builders of North Carolina (surveying the state of building in North Carolina from 1730-1830), found that most of the state was rural, with buildings often built cheaply, quickly and of wood. Population growth in the Piedmont was slow until the late 1700s, therefore, brickmaking remained a seasonal, local occupation well into the 1800s. The limited records available make it difficult to find detailed information on early brickmakers other than occasional names (pp. 75-111).

Migration into the Piedmont, however, came from a different direction with groups generally following the Great Wagon Road from western Pennsylvania through the Shenandoah Valley of Virginia into central North Carolina. Early migrants were mostly German, English, and Scots-Irish, but also included two specific religious groups: Moravians and Quakers. Many of these immigrants came from brickmaking traditions, but were slow to utilize the abundant natural resources for brick simply because the time and energy required to fire brick was extensive, and seasonal. Clamps built onsite were dismantled once building wascompleted, often leaving little documentation.

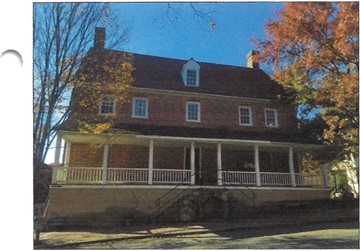

Fig. 6: Oversized early bricks by Krause juxtaposed with a newer addition. Salem Tavern, 1784.

The major exception to this generality was the Moravians, thanks to meticulous records kept by local governing boards. Moravians (from Bohemia and Moravia) established a settlement in Pennsylvania during the 1740s, purchasing anotherl00,000 acres in North Carolina during the 1750s. Naming the tract Wachovia, they quickly constructed the three towns of Bethabara, Bethania and Salem-all in or near the modem town of Winston-Salem. These first settlers were generally the tradesmen and artisans needed to build and supply each town including, in 1755, mason Melchior Rasp. By 1766, Rasp is recorded as a "master mason," but documentation indicates he was working in both stone and brick. As he ages, however, records note the lack of masons in Salem with growing concern, and in 1781, Johann Gottlieb Krause was released from a pottery apprenticeship and reassigned to Rasp.

Krause, born in Bethabara, already had experience working with local clay outside pottery as Moravian buildings often utilized clay tiles for roofing rather than the locally common wooden shingles. Following Rasp's death, Krause became the leading mason for Salem, and by 1783, was also managing the Salem brickyard. Post Revolution, brick became the building material of choice in Salem, even though it appears that brickmakingand brick laying were still learned mostly through experimentation. His early bricks were oversized with a weight that made bricklaying difficult (requiring both hands to set the brick) and he favored manually producing each needed brick size rather than simply breaking bricks for various purposes. (Early Krause bricks measure 12" x 51/2" x 3" as compared to 8" x 35/8" x 21/4'' for a modem standard brick.)

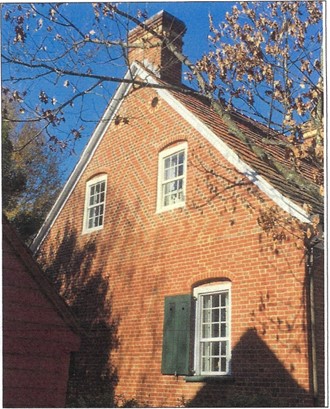

Fig 7: Christoph Vogler House, Salem, 1797. Built by Krause after his collaboration with Craig, it features a chevron pattern and glazed headers.

Fig 7: Christoph Vogler House, Salem, 1797. Built by Krause after his collaboration with Craig, it features a chevron pattern and glazed headers.

In 1793, Krause began work on a new schoolhouse in Salem (the Boys School), along with William Craig, a non-Moravian who worked in the English brick making tradition rather than the Germanic tradition favored in Salem. Regrettably, very little is recorded about Craig specifically because he was non-Moravian, even though he was instrumental in creating a new, patterned method of laying brick. His influence on Krause is evident as bricks became smaller and more uniform, enabling a standardization of bricklaying. Decorative brickwork that included lozenges, herringbone, and even letters from the Flemish and English bricklaying tradition now merged with Germanic tradition in Salem, quickly becoming popular throughout the Piedmont.

Following a dispute over wages, Craig left Salem (possibly moving to Salisbury, NC), but buildings built by Krause in Salem after their collaboration were far more sophisticated, detailed, and standardized than before, establishing a new methodology of brickmaking and bricklaying for future generations (Bishir, pp.112- 120; http://ncarchitects.lib.ncsu.edu/people/P000l33; P000134; P000135).

Fig. 8: A visual guide to extruded brick styles. Fig. 9: Pressed brick in the Foust Building, UNC Greensboro, 1892.

Fig. 8: A visual guide to extruded brick styles. Fig. 9: Pressed brick in the Foust Building, UNC Greensboro, 1892.

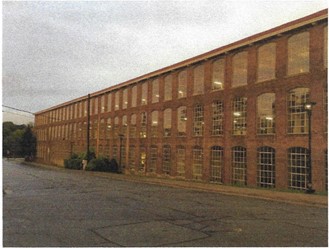

North Carolina remained a largely agricultural state well into the twentieth century, with a variety of brickmaking techniques existing simultaneously. Expansion of the railroads and the increasing mechanization of the building trade helped spur increased production in the larger cities, particularly after a series of devastating fires in both Fayetteville and Raleigh that included the loss of North Carolina's State House. Demand for brick as a fire-proof building material skyrocketed, driven partly by the need to protect the increasingly valuable tobacco trade. During the second half of the nineteenth century, a flurry of patents were filed which included: a brick machine invented by Allen and Duffy of Greensboro that could grind the clay and press brick simultaneously- producing "eight to ten thousand well pressed brick with perfect comers and edges;" a steam-powered "Traction Brick machine" from Raleigh mechanic William Cram that reduced the time required for tempering to a few hours; and improvements in kiln burning methods that regulated temperatures and reduced fuel consumption by Daniel Ashbury of Charlotte (Lounsbury, 234). Each of these improvements lowered the water content of the clay, thus reducing the drying time while creating a stronger end-product. This stiffer product could now be extruded in a continuous bar, cut into individual bricks mechanically, then loaded onto kiln cars for the journey through the drying and firing tunnels. Whether extruded or pressed, brickmaking rapidly standardized with sharper edges, smoother surfaces, and a new capability for more consistent color (Lounsbury, 234). These industrialized processes became the foundation of North Carolina's first brickmaking companies. It is important to note, however, that during this same time period, brickmaking in rural North Carolina lagged far behind these industrial advances. Mechanization was achieved mostly through improved pug-mills, which could be purchased for a reasonable amount, produced a stiffer product, utilized multiple molds, and could be powered by either horse or steam engine. Shrinkage was reduced thanks to the lower moisture content of the stiffer clay, resulting in sharper edges and a more uniform appearance. This method, however, still required that the bricks be hand stacked in hacks to dry and fired in traditional clamps ((Lounsbury, Architects, 232). The result is brick that combines the visual hallmarks of both hand molded and extruded brick.

More standardized in size and shape than hand molded (with the sharper edges of the extruded method), it often bears the markings and variations in strength and color that result from clamp firing. Brickmaking in the Piedmont ranged from traditional, hand molded through pug-mill/pressed to standardized extruded simultaneously until WWII. For example, building the Reynolds Tobacco Company warehouses (Winston Salem) in the early 1900s required so much brick that R.J. Reynolds was forced to simultaneously purchase both factory-made brick and local hand-made brick.

As brickmaking industrialized in Piedmont cities, brickmakers founded companies that remain in the same families today. (Although of an original 30 family-owned companies, only seven presently remain family-owned.) On its website, The Statesville Brick Company claims the title of oldest family-owned brick manufacturer in North Carolina, founded in 1891. They are known for their "state of the art" alternative fuel system that utilizes wood and specialize in "tumbled" brick-straight edge brick tumbled to appear old. Pine Hall Brick, also of Statesville, was founded in 1889 and its website proudly proclaims that although it still produces standard brick, is the now the largest producer of clay avers in the United States. Ongoing family companies founded in the 1950s include Triangle Brick Company of Durham and Lee Brick of Sanford. Thanks to its abundance of shale (rock composed of very fine clay particles) and clay, North Carolina remains one of the principle brick producing states in America, now exporting brick around the country.

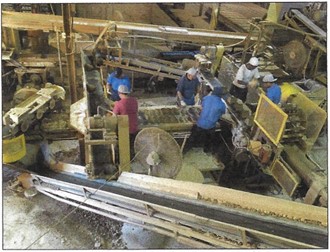

Fig. 10: Fingerprints in hand thrown brick, Fig. 11: Overview of soft mud being hand thrown into the mold Old Carolina Brick. as it heads towards the scraping device.

Old Carolina Brick Company

Perhaps the most unusual brick manufacturer in North Carolina, Old Carolina Brick Company (Salisbury) continues the tradition of hand molded brick, now combined with a gas-fired tunnel kiln and mechanized drying racks. Shale (dug locally in Gold Hill) is run through a modern pug-mill, producing the individual clay mixture needed for each order. The mud is then manually thrown into sand coated molds rolling along a conveyor belt. (The chemical composition of a particular sand helps produce specific brick colors.) Excess mud is skimmed off by piano wire through a mechanism labeled the Strike-off, then the bricks are mechanically turned out onto drying racks. Each load will dry for eighteen to twenty-two hours at about 300 degrees F, reducing the water content from 30 percent to about 1 percent. Once dried, bricks are manually stacked into hacks on kiln cars, which then proceed through the tunnel kiln. An average load will fire for two days at about 2000 degrees F, but the firing time and temperature are dependent on the type of brick, shape, and desired color. A major benefit of handmade brick is that manually manipulating the mud creates natural air pockets (open to the surface), which allow water to freeze and thaw without cracking the brick (Southern Living Write Up).

Although Old Carolina Brick mixes handmade and mechanized teclmiques, their bricks retain the markings of handmade brick. As Vice-President Art Burkhart describes, "Each has its own characteristics, with fingerprints and folds-like when you make a pie and the dough folds over" (Period Home Write Up). They are the largest handmade brick producer in America and have participated in numerous historic restoration projects that include Mt. Vernon, Williamsburg, Charleston, Monticello, Old Salem, and Yale University. Vice-President Brian Cleveland explained that matching brick in a historic preservation project can be time consuming as finding the right sand/shale mixture along with the correct firing time and temperature may take numerous sample loads- and will certainly require an experienced eye. Founded in 1968, Old Carolina Brick Company was bought by Dudley P. Frame in 1972 and is today run by his two sons, Presidents Scott and David Frame, who, along with each Vice-President, consider their business a labor of love.

George Black- MasterBrickmaker

George Black is significant in Piedmont brick history for several reasons. One, little is often known about brickmakers or smaller brickyards outside their names, therefore, the extent of documentation on Black is historically significant. Two, Black continued to make brick in the traditional, handmade method throughout his eighty-year career, simultaneously functioning as both a traditional artist, and as living history. Lastly, Black's expertise and reputation led to nationally televised interviews, a meeting with President Nixon, and a State Department sponsored foreign aid mission to Guyana specifically to teach brickmaking.

George, along with his father (a former slave) and brother, found work at the Hedgecock and Hime Brickyard in Winston -Salem in 1889. George star ted as a "off-bearer" (carrying the wet bricks to the hack for drying), but gradually learned the entire brickmaking process. At some point, Hedgecock gave George a broken wooden mud mill, (an early type of pug-mill), expecting him to use it for firewood. George, however, repaired and rebuilt the mud mill in his backyard, and began making brick there when not at work. By the 1920s, George is variously recorded as owning his own brickyard, or partnering with former coworkers from Hedgecock and Hime. He quickly gained a reputation for producing high quality brick which led to contracts for local homes, and with R. J_ Reynolds for his tobacco factory buildings, the "Old Main" Baptist Hospital, and Colonial Williamsburg for "reconstruction" bricks. During the 1940s and 50s, he supplied brick for restoration at Old Salem as well as for various Wachovia Bank branches.

In 1970, at the age of 91, George was interviewed by Charles Kuralt, which led to the meeting with President Nixon and trip to Guyana. He also returned to Williamsburg, serving as a consultant for a brickmaking exhibit. He continued to use his mule powered mud-mill until his death in 1980 at 101 years of age. His bricks are treasured today, still functional and reused whenever possible. His former home and brickyard are on the National Register of Historic Places, and designated a local landmark (Oppermann, pp. 8.4-8.10).

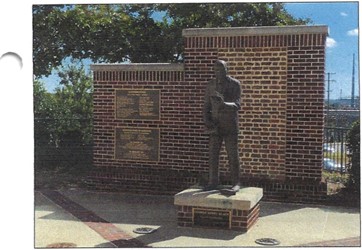

Fig. 12: The George Henry Black Memorial in Winston Salem, NC, which displays Black's hand-made brick surrounded by modern brick.

Fig. 13: Hand signed brick in the Charles Benbow House of Oak Ridge, NC with building date, number of bricks fired, and initials.

Conclusion

Requiring only a few, natural components, and today made quickly through a mechanized process, brick may seem a simple, cheap building material. As illustrated in this brief, however, it remains an artform, even in its industrialized state. Clay, shale, sand, and water abundant in the Piedmont- must still be blended precisely to create the requested product. North Carolina's legacy of brickmaking and brick artisans continues today, with buildings in the Piedmont containing many fine examples of hand-molded, pressed, and extruded brick. These bricks proudly convey the significance of North Carolina's brickmaking heritage even as our brickmaking tradition embraces the future.

Fig . 14: Salem Tavern, 1784. Bricks and roof tile by Johann Krause.

Fig. 15: Revolution Cotton Mill, Greensboro, NC

Bibliography

Bishir, C. W., Brown, C. V., Lounsbury, C.R., and Wood,

E. H. (1990). Architects and Builders in North Carolina: A History of the Practice of Building. Chapel Hill, NC: The University of North Carolina Press.

Broeksrnit, S. B., and Sullivan, A. T. (2006). Dry-Press Brick: A Nineteenth-Century Innovation in Building Technology. APT Bulletin: The Journal of Preservation Technology, 37(1), 45-52. Retrieved from https://www jstor-org .libproxy.un cg.edu/stable/40004680?Search=yes &resultltemClick=true&searchText=preservation&searc hText=techniques&searchText=for&searchText=brick&se archUri=%2Faction%2FdoBasicSear ch%3FQuery%3Dpr eservation %2Btechniques%2Bfor %2Bbrick&refreqid=se arch%3A4d205ced48925a739c9a45235ec46e41&seq=1#pa ge_scan_tab_conten ts.

Campbell, J. W. (2003). Brick, A World History. New York, NY: Thames and Hudson Ltd.

Elliott, C. D. (1992). The Development of Materials and Systems for Buildings. Cambridge, MA: The MIT Press .

Gagne, N. The Art of Handmade Brick. Retrieved from https://www.handmadebrick.com/ABOUT/Traditional_ Product_Reports_Write-up/.

Henry, A., McCraig, I., Willett, C., Godfraind, S., and Stewart, J. (Eds.). (2015). Earth, Brick, and Terracotta, Part Two. Burlington, VT: Ashgate Publishing Company.

Johnson, M. (August 2011). Forged from the Soil. Our State. https://www .ourstate.com/north-carolin as-brick industry/.

McKee, H. J. (1973). Introduction to Early American Masomy. Washington, DC. The National Trust for Historic Preservation and Columbia University.

Old Carolina Brick Com pan y. Period Home Write up. Retrieved from https://www.handmadebrick.com/ ABOUT/Period_Home_Write-up/.

Old Carolina Brick Company. Southern Living Write Up. Retrieved from https://www.handmadebrick.com/ ABOUT/Southem_Living_Write-up/.

Old Carolina Brick Company. Technical Information. Retrieved from https://www.handmadebrick.com/ BRICK_OPTIONS{fECHNICAL_INFORMATION/.

Oppermann, L. E. (1998). National Register Nomination for the George Black House and Brickyard, Forsyth County, North Carolina. Forsyth County Department of Planning and Community Development.

Pulice, M. (June 2006). Machines for Making Brick in America, 1800-1850, The Chronicle of the Early American Industries Association, Inc., 59(2), 53-58. Retrieved from https://search-proquest-com.libproxy.uncg.edu/docview

/203690484?0penUrlRefld=info:xri/sid :wcdiscovery&acc ountid=14604.

Statesville Brick Company. Retrieved from http://www. statesvillebrick.com/.

The Carpenter's Company of the City and County of Philadelphia, (1976). Building Early America. Charles E. Peterson (Ed.). Radnor, PA: Chilton Book Company.

Photo Credits

Figures 1-7: Author

Figure 8: Imag e by Richard Luxenburg, Professor of Architecture, Anne Arundel Community College. Retrieved from https://www.slideshare.net/richlux/brick masonry-fall-09

Figures 9-15: Author

Acknowledgments

Special thanks to the following for graciously giving of their time during interviews that substantially contributed to this brief: David Bergstone, Director of Architecture at Old Salem Museum and Gardens (September 2017 ); David P. Frame, President, Art Burkhart, V P., and Brian Cleveland, V P. of Old Carolina Brick Company (September 2017); and Michelle McCullough, Project Planner for the City of Winston-Salem, NC (October 2017).

The Historic Dimension Series is a collection of briefs prepared by UNCG students under the direction of Professor Jo Ramsay Leimenstoll. For information on other topics in the series please visit the website at www.uncg.edu/iar/hds